We undertake the design and manufacture of medical instruments. Get in touch with us!

make@ap-x.hu

Medical Instruments

- Originally, the main activity of our company was the development of medical instruments. We have been involved in projects in many other areas over the years, but if we can, we will try to do as much health-related R&D as possible. Some examples from recent projects:

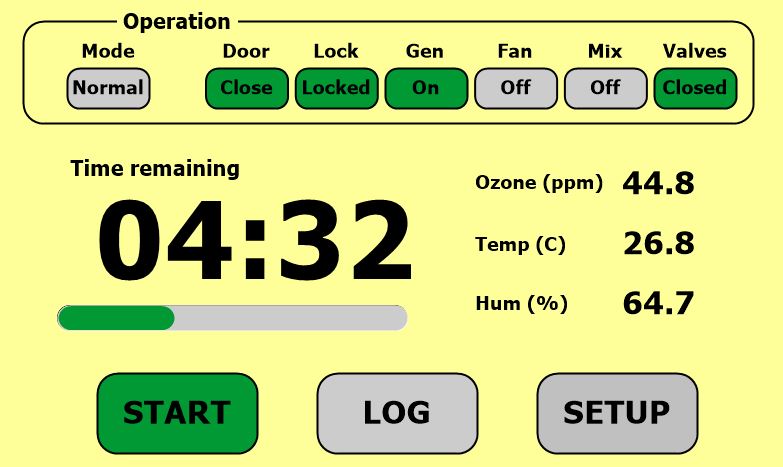

Ozone disinfectant / sterilizer

Screenshot and the touch-display of the device

What is the difference between them?

Disinfection and sterilization are not synonymous in medical terms. During disinfection, a much smaller percentage of potential pathogens are destroyed than in the case of sterilization, where this value is practically 100%. The difference between the two levels also determines the way the methodology. Surgical instruments must be sterilized. It is safest for metal devices to use water vapor (steam) at temperatures above 130-150⁰C for an appropriate period of time (60-180 min). Devices that do not tolerate this effect are usually sterilized using some (also harmful to humans) toxic gases. Sterilization processes are very slow, in any case taking more than 1 hour. In many cases, this level of sterilization is not required, e.g. for foodstuffs. However, the Covid-19 epidemic points out that reducing the number of pathogens by 80-85 — possibly 90% — can greatly reduce the number of infections. This is especially important for the high-risk population. Therefore, from a tender source, we have developed a device that can be used mainly in hospital wards, obstetrics and nursing homes, which mainly disinfects food. Our prototype serves the latter purpose by quickly disinfecting its content (max 12-14kg).

Operation

Pathogens are eliminated using ozone gas, which is non-toxic (above certain concentrations, may be harmful to health at prolonged exposure and irritating). Ozone decomposes in the open air in a short time. The duration of the disinfection session is much shorter (10-30 min), the O3 concentration ranges from 15-60 ppm. Based on literature data, this dose does not impair the consistency of foods, but at the same time kills a significant part of pathogens. Microbiological tests are currently underway, the results of which can be reported later. According to some ideas, the product may be used in the food trade at a later date. Most of the used gas can be eliminated at the end of the process, a smaller part, when released into the open air, does not cause environmental damage or pollution.

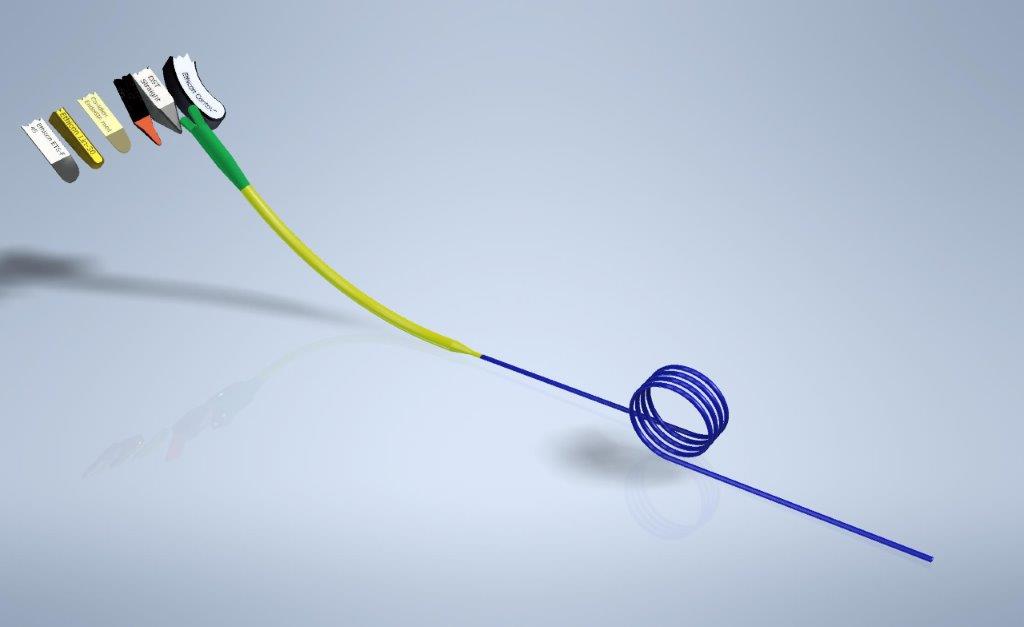

StapLead

In this project, which is also tender-funded, we have developed a a device that facilitates the introduction of tissue-sewing machines into the operational area during various (usually abdominal and thoracic) surgical procedures. Sewing machines actually place staples arranged in several rows in the area to be sealed. The staples are placed in magazines, several of which are usually used during the operation process. To replace the magazines, the device must be removed from the surgical area each time and then re-introduced to the appropriate location after refilling. This type of multiple positioning is a very time consuming and precise operation that requires a lot of attention. The tool is used to facilitate (and thus speed up) positioning.

We are currently working on 3 more product development projects, the future development of which we will report on. These:

- Sternum lifting device, which, unlike other similar devices, is specially designed for chest / sternum plastic surgery.

- Development of an electromechanical device to automate the placement of adhesive fasteners (Brackets) used in orthodontics.

- Development of a thoracic endoscopic device for rapid fixation of the ribs of patients who have suffered a (series) rib fracture during an accident.

Over the years, we have also been involved in many other medical technology developments as subcontractors.

- Monitor-matrix mounting frame in operating room

- Surgical camera system

- Motion control software for C-arm X-ray unit

- 3D imagination of movement of endoscopic devices

AP-X produces custom design medical equipment in small series. Do you need a special mechanical or electronic device that cannot be found in the market? We help you to develop your own one.